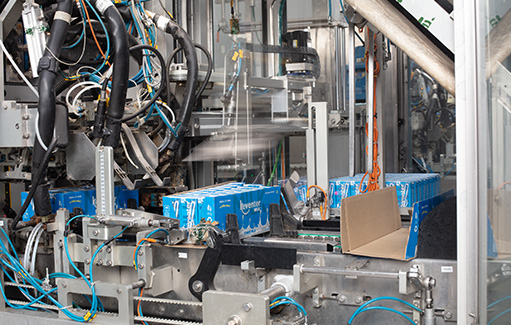

Our state-of-the-art manufacturing infrastructure, superior sourcing and stringent

quality and food safety procedures

Flagship facility at Barasat, West Bengal – spread over 92 acres and consists of multiple processing units. Only UHT milk processing and packaging unit in East and North East India.

Our food processing units located at Durgapur, Midnapore, Siliguri and Patna. Involved in processing and manufacturing of products under the dairy & fresh segment.

We are also in the process of establishing a food processing unit at Ranchi.